Future Food #3: The unreasonable effectiveness of plants

Despite their inefficiency, plants will remain the foundation of our food supply

So far, I've covered trophic levels, the inefficiency of modern food production, and the promise of artificial photosynthesis, where solar panels and bioreactors become a foundational platform in our food supply.

Due to the far superior efficiency of photovoltaic cells at capturing sunlight, using electricity and microbes to produce synthetic foods could be 10x more land efficient than growing staple crops like soybeans. It is also true that solar farms can generate many times more revenue per hectare than agricultural farms.

So, will most of our food be grown with solar panels and steel tanks in the future? I’m still not convinced.

It’s time to give plants their time in the sun.

Nature’s wealth printers

I’ll start by highlighting how incredible plants are.

Like photovoltaic cells, plants are machines that print out wealth from thin air. They’re self-assembling, biodegradable, biological factories that turn free air and sunlight into a wide variety of complex and useful products. And anyone can learn how to grow them.

The set of things you can manufacture using plants is vast: cereals, fruits and vegetables, fats and oils, spices, stimulants, fibers, wood, fuels, and even drugs and vaccines.

A few gigabytes of genetic firmware1 contain the instructions for autonomous factories that produce rice, or bananas, or avocados, or maple syrup, or blue tomatoes, or milk proteins, and so on down a list of about 380,000 known plants. That’s pretty remarkable.

In the past, humans discovered plants that do useful things and selectively bred them. Now, we’re starting to engineer and edit them. In the far future, we might engineer synthetic plants from scratch, giving them enhanced or new-to-nature properties.

Advantage #1: Lower capital costs

While plants might lose in a head-to-head battle with biomass fermentation on energy and land efficiency, they are an obvious winner when it comes to capital costs. This is perhaps their biggest advantage; crops are mostly grown outdoors with minimal supporting infrastructure, and self-assemble from tiny seeds that are easy to distribute.

My time so far at Synonym has taught me just how much it costs to build industrial fermentation facilities. The building, bioreactors, tanks, centrifuges, dryers, construction fees, etc, add up to tens or hundreds of millions of dollars. Our financial models often include a multi-million-dollar line item for paint! Paint! Each facility involves an incredible number of engineering hours to design and several years to build. Even amortized over 20+ years, the total installed cost of the facility and the cost of capital can be a significant fraction of the”fully-loaded” cost-of-goods-sold.

The chart above shows an illustrative CAPEX breakdown for an example ~$400M yeast biomass fermentation facility located in the US Midwest. I modeled this facility using Synonym’s Scaler tool. The facility uses a fed-batch yeast biomass process to produce 50,000 MTPY of biomass.

There are many routes to reducing CAPEX, like standardizing facilities, doing continuous fermentation, and strain optimization. But even with excellent processes, financing large-scale facilities like this will remain a key challenge for biomanufacturing startups.

The expense and effort involved in building food-grade steel infrastructure makes “low-tech” solutions like plants look all the more attractive. You might argue that modern farming also includes expensive equipment, and places like the Netherlands have a lot of greenhouses2. But the infrastructure for conventional farming is comparatively cheap, and is already deployed widely. If you develop an improved crop variety, there are millions of square kilometers of farmland ready for your innovation to be deployed on with low up-front investment. The same biomanufacturing infrastructure does not exist (yet).

Advantage #2: Fewer and cheaper inputs

Even in a world where biomanufacturing infrastructure is widespread, it would still be difficult to compete on cost with commodity crops. I’ll start with some intuition, and then dive into the techno-economics for proteins, carbohydrates, and fats.

For the same biomass fermentation facility modeled above, I’ve plotted a breakdown of the cost-of-goods-sold (COGS) in $/kg.

At large scales (like this facility), the feedstock (sugar and nitrogen) starts to become the biggest cost, followed by financing costs (paying back investors). For fermentation, you also have to pay for your energy and carbon source, which is usually sugar (e.g dextrose). For plants, the energy/carbon source is free sunlight and air.

Besides feedstock, there are also a lot of tiny operational costs that add up, creating a sort of “death by a thousand line items” situation. To run a fermentation facility, you need to pay for utilities, minor consumables, administrative costs, labor, taxes, insurance, and so on. None of these costs are large on their own, but together they represent about a third of COGS in this example.

Proteins

For sustainable and affordable protein production, the two competing options in my view are crops and biomass fermentation.

To be clear on terminology, by biomass fermentation I mean growing and harvesting whole microbial cells. This is in contrast with precision fermentation, where we separate a target molecule from the biomass.

In the chart below, I compare the input costs of several protein production scenarios on a $/kg, 100% dry protein basis:

BF-Glucose: Biomass fermentation, using primary sugar (corn dextrose)

BF-Upcycled: Biomass fermentation, using upcycled crop sidestreams (see this GFI report)

BF-Methane: Biomass fermentation using green methane produced via renewable electricity.

Protein isolates of several commodity crops (soy, wheat, peas, chickpeas) and livestock (beef, pork, chicken). Protein isolates are similar to the dried and purified biomass you’d get from fermentation.

You can find the modeling behind this chart in my supplemental data. For crops and livestock, the cost ranges are based on the historical high and low commodity prices from the last 20 years. For fermentation, I’ve chosen what I believe to be pessimistic and optimistic values for feedstock costs and CAPEX.

From this chart, we can make a few conclusions:

You can’t feed the world affordably using livestock, especially beef and pork. This is mainly due to thermodynamics and extreme caloric inefficiency.

Biomass fermentation (BF-*) prices overlap with commodity crop prices, suggesting that they are economically favorable in regions/scenarios where crops are expensive.

Commodity crops are very cheap. At their historical lows, soy and wheat are by far the cheapest source of protein (by a factor of > 2 over BF). This is impressive, since these crops have perhaps 40% and 15% protein content on a dry basis.

Crops and livestock are subject to significant price volatility. The controlled environment of fermentation allows for more stable and predictable output prices.

Let’s zoom in on the crops and biomass fermentation, since beef has basically ruined our x-axis range.

From this view, I want to emphasize just how cheap crops are. In the most optimistic biomass fermentation scenarios, they’re just barely reaching the average commodity prices for wheat and soy.

We’ve also chosen a comparison metric ($/kg dry protein) which heavily favors fermentation. Biomass fermentation can be optimized for edible protein production (~65% dry protein content) whereas soy and wheat have only ~40% and ~15% dry protein content, respectively. Effectively, the crops aren’t getting any credit for the calories they produce as carbohydrates, fats, and inedible biomass. If we looked at soy protein meal instead (just ground up soybeans) prices are in the $0.20-0.50/kg range.

Using upcycled crop feedstocks could reduce fermentation prices a bit (BF-Upcycled), but the potential cost reductions I’ve taken from this GFI report are a bit underwhelming. The BF-Upcycled scenario also assumes that the microorganism has been metabolically engineered to accept both C5 and C6 sugars (“total sugars”). I’m generally skeptical of upcycled feedstocks, since we still don’t have cellulosic ethanol after 20+ years of effort and billions in funding!

Biomass fermentation using synthetic feedstocks (e.g methane, methanol, formate) has the best-looking economics in the long term, though crops may still remain cheaper. It’s also worth noting that the “BF-Methane” pathway is the only one in my chart that does not depend on arable land!

Takeaways: Most of our future protein will still come from crops. Biomass fermentation is a promising route, but a lot of things need to go right in order to compete with protein isolates from crops like wheat and soy. In regions with very limited arable land (e.g Singapore, Greenland, Egypt), fermentation using synthetic feedstocks like methane makes a lot of sense. Sustained increases in commodity crop prices could also accelerate the adoption of fermented protein ingredients.

Detour: What about land use?

For producing protein, fermentation can be extremely land-efficient.

Biomass fermentation using H2/CO2 is a massive improvement in land use (~14x). This OOM improvement is primarily due to the superior efficiency of solar panels when compared to biological photosynthesis.

Even with sugar feedstocks from commodity crops, fermentation can be 2-3x more land efficient at producing protein! This seems counterintuitive – shouldn’t it be more efficient to just grow crops for humans, rather than growing crops to feed to microbes?

This is a result of the metabolic capabilities of plants vs. microbes. Plants have evolved to be excellent at manufacturing carbohydrates and using them as energy storage or structural materials, while microbes are efficient protein factories that are packed with ribosomes. Microbes also don’t need to build durable and rigid carbohydrate (cellulose) structures to support themselves against gravity. Fermentation leverages the strengths of both types of organisms: plants make sugar, and microbes turn sugar into protein.

What if we compare on a calorie basis, instead of protein?

Comparing the calorie efficiency of land, plants are more competitive with fermentation. However, the synthetic pathways (BF using H2 + CO2 or CH4) are still clear winners: 5x more land efficient than soybeans, 2-3x better than corn, and ~50%-80% better than sugar beets. Sugar fermentation is now less land efficient than sugar crops at producing calories, in agreement with our thermodynamic intuitions.

Carbohydrates

As we saw above, commodity crops are well-suited for producing carbohydrates. Sugarcane and sugar beets are the most extreme cases, and approach the productivity photovoltaic-powered fermentation on a calories per unit area basis.

For producing the world’s carbohydrate supply, plants are really the only viable solution I’m aware of. In the last post, I wrote about the possibility of cell-free carbohydrate synthesis – replicating photosynthesis in a reactor using enzymes. I don't believe that process will be cost-competitive any time soon. Consider the ASAP Cycle as an example, which was experimentally shown to be more efficient than crops at converting hydrogen/CO₂ or methanol into starch. In this CO₂-to-carbohydrate pathway, there are 20+ unique enzymes needed. Each of these enzymes needs to be produced in a microbial host, extracted, isolated, and purified – so you need a mini fermentation process just to supply the reagents for your main process. The enzymes wear out over time and need to be replenished. You probably also need to immobilize them somehow, and physically separate some of the reactions, as in the paper. In their pure form, enzymes can cost anywhere from tens to hundreds of $ per kilogram to manufacture. Finally, you need to regenerate cofactors (e.g ADP→ ATP and NADP→ NADPH) to drive the synthesis reaction3.

It’s also theoretically possible to make carbohydrates using a chemical process, but difficult in practice. To recap, the formose reaction isn’t very selective produces equal amounts of L-glucose and D-glucose, as well as a bunch of carbohydrates of varying chain length. For whatever reason, biology on Earth evolved to prefer D-glucose. L-glucose tastes like sugar, but we can’t metabolize it, and its long-term health effects aren’t well understood.

In sum, carbohydrates involve stereochemistry, and stereochemistry generally requires biology. If the selectivity issues could be overcome, I believe you could produce synthetic sugar at current commodity sugar prices with very cheap electricity in the < $10-20/MWH range (see this paper).

Takeaways: I’m not confident that we won’t have a breakthrough in catalysis that makes a synthetic glucose/starch pathway viable. But even if we did, we can’t feed the world a diet of pure glucose and starch. I believe plants will remain the foundation of a (healthy) carbohydrate supply.

Fats

Time for a hot take.

Everyone likes to blame palm oil for deforestation, but oil palms are incredibly productive, and deforestation would actually be many times worse if we used any other oil crop as an alternative! That’s because the next best alternative, rapeseed oil, is about 4x less productive per unit area, meaning that you’d need 4x the land to meet demand.

Fermentation is a possible route for producing alternatives to palm oil and other fats, since some yeasts and other microorganisms naturally produce lots of lipids. For example, C16 Biosciences was founded to create a yeast-produced alternative to palm oil, citing the environmental destruction and deforestation it causes.

The problem is that sugar-fermentation-derived oils are not a win from either a land use or cost perspective. Yeasts are typically fed sugar or methanol, and as far as I can tell from public information, C16 uses sugar. Below, I modeled the land use of palm oil (world average) vs. sugar fermentation vs. a thermochemical process like Savor.

Even if we assume the maximum metabolic efficiency for converting glucose to lipids, a C16-like fermentation process is about as land-intensive as oil palms. Not all land has the same ecological value, so there might still be good reasons to farm sugar crops instead of oil crops. Regardless, I don’t see how C16’s claim of 250x more efficient land use could possibly be true. For what it’s worth, I’m still rooting for C16 and their peers, and I’d love to see my modeling proven wrong.

Thermochemical fats, produced via renewable methane or H2/CO2, could offer a massive reduction in land use (~6x). I’ll note that my estimate above is extremely overoptimistic: I’m only considering the energy requirements for feedstock, and not the fat production process itself. But even at half the efficiency I’ve calculated, we’re still looking at a ~3x reduction in land use. I don’t know the details of Savor’s process, but thermochemical (synthetic) fats seem to be a win across emissions, land use, and product functionality.

What about cost?

Once again, plants set a tough price benchmark. Fermentation using sugar almost certainly won’t become cost competitive, since you need several kilograms of sugar to produce 1 kilogram of fat (source), and commodity sugar prices are similar to commodity oil prices. In my opinion, fermenting food using sugar crops is a technological dead-end, unless you’re producing products with very unique or valuable properties (e.g dairy proteins) that are uneconomical to produce and extract from plants. Thermochemical fats could reach price parity at green methane prices of ~$10/kcf and low CAPEX, but I expect commercial scale up to take some time.

Takeaways: In the short-to-medium term, oil crops will continue to supply most of the world's fats. Eventually, I believe a thermochemical process that uses renewable H2/CO₂ or CH4 could reach price parity, with obvious benefits for land use and sustainability. For now, I’ll defend the unpopular opinion that oil crops are quite good at what they do! We should try to make them even more productive and resource-efficient if we can.

Room to grow

Coming into this research, I assumed that crops must be near the limits of productivity. Haven’t all avenues for improvement been exhausted by centuries of agricultural progress? But now I believe there is significant room for improvement – not just in crop yields, but in the industrial capabilities that plants can offer.

In the chart above, we can see that staple crop yields have improved remarkably over the last ~60 years4. The key questions are, can we extend this trend, and how do we accelerate it?

Photosynthesis is naturally speeding up

As the ppm of CO₂ in the atmosphere gets higher every day, photosynthesis actually speeds up in a process called CO₂ fertilization5. Researchers at Berkeley estimated that the global rate of photosynthesis has sped up by 12% between 1982 and 2020 due to CO₂ fertilization. Because plants evolved at pre-industrial atmospheric CO₂ concentrations (~30% lower), we might be able to improve yields even more by metabolically adapting them to current CO₂ concentrations.

Of course, climate change also leads to more extreme and unpredictable weather. In some places, any “benefits” from CO₂ fertilization are offset by droughts, warmer climates, too much rainfall, etc. So CO₂ fertilization is a bit of a pyrrhic victory; we’re trading a mean for a much higher variance. Our World in Data has a great piece on the tradeoffs of climate change for crop yields.

Photosynthesis can be improved

There is a theoretical upper bound on efficiency of about 12% for photosynthesis. The chemical reaction that turns CO₂ into glucose itself (Calvin Cycle) is about 30% thermodynamically efficient, and plants can only capture and utilize the energy from 45% of the sunlight spectrum. Other inefficiencies stack on top of this, like photorespiration, self-shading, reflection, excess photons that are wasted as heat when sunlight is too intense, and less productive phases in a plant’s life cycle, and so on. As a result, the practical efficiency of crops is usually below 1%, less than 1/10th the theoretical limit.

This fascinating 2011 paper by Blankenship et. al. lays out a menu of options for improving photosynthetic efficiency.

You could find variants of the RuBisCO enzyme that are better suited to modern CO₂ concentrations, or more selective for CO₂ in general

You could replace the Calvin Cycle (dark half of photosynthesis) with a new and more efficient CO₂ reduction pathway. The reductive glycine (rGly) pathway is a particularly efficient example that has been implemented in a few organisms.

You could bypass photorespiration - this is what Living Carbon has demonstrated!

You could redesign the light reaction of photosynthesis so that its two photosystems absorb photons from separate halves of the sunlight spectrum. Instead of competing for photons in the same range of wavelengths, they would operate in tandem across a spectrum that’s twice the width. Very crudely, this could double the theoretical efficiency of photosynthesis, from 12% to 24%, though this would probably involve multiple Nobel-prize-level breakthroughs.

Maybe some of these strategies are dead ends in the idea maze – I haven’t done enough research yet to know for sure. But given the gap between actual efficiencies (<1%) and theoretical efficiencies (12%6) it seems plausible to me that we could, say, double the rate of photosynthesis in crops. Despite doubling crop yields since the 1960s, plants are still only sipping from a firehose of photons.

Reducing or eliminating nitrogen fertilizer use

About 5% of global emissions come from nitrogen fertilizers7 alone, so reducing or decarbonizing fertilizer is absolutely on the critical path of getting to net zero. We can’t just get rid of fertilizer – without it, we could only feed 3.5B people instead of 8B8. Fortunately, there is a portfolio of strategies for decarbonization, including applying fertilizer more effectively, scaling green ammonia production, engineering nitrogen-fixing bacteria, and distributed plasma reactors.

Some plants, like soybeans and other legumes, get a significant fraction of their nitrogen through a symbiotic relationship with nitrogen-fixing bacteria near their roots. The plants provide sugar to the bacteria in exchange for nitrogen in an elaborate handshake, which I find kind of heartwarming. Companies like Kula Bio are enhancing the natural nitrogen fixation capabilities of these symbiotic microbes (e.g Xanthobacter).

Why haven’t all crops evolved this collaborative nitrogen strategy? It costs a lot of energy to fix nitrogen, so plants would need a strong evolutionary reason not to just extract it from the soil for free. Reducing one N2 molecule into 2NH3 requires at least 16 ATP worth of energy for the microbe. One molecule of glucose can produce ~32 ATP through aerobic respiration, so the exchange rate is at best 4 molecules of NH3 per 1 molecule of hard-earned C6H12O6, or 1.5 carbons per nitrogen. For a plant with a 20:1 C:N ratio in its biomass, that would mean that at least 7.5% of energy must go to nitrogen synthesis in the form of sugars secreted at the roots (1.5 carbons spent out of each 20 earned). Luckily, any of the photosynthesis improvement strategies listed above could give plants the additional energy they need!

An even more elegant strategy would be to introduce synthetic nitrogen fixation pathways directly into plants, and researchers are indeed working on this. A challenge is that the key nitrogenase enzymes are damaged by oxygen, which is abundant inside of plant cells. Significant bioengineering work is needed to add oxygen protection, for example by containerizing nitrogen fixation in its own synthetic organelle. The upside of integrating nitrogen fixation into crops would be massive, especially for the poorest farmers who probably can’t afford synthetic fertilizer.

Molecular farming

A relative newcomer to the alt-protein space is molecular farming, where plants are genetically modified to produce non-native proteins of interest. It’s a cool idea: to replace animal products, steal their genetic secret sauce and put it in crops. For example, Alpine Bio recently harvested soybeans that contain casein (the key protein in dairy and cheese), Moolec grows soybeans that taste like pork, and IngredientWerks is adding cow myoglobin (heme protein) to corn.

We can divide most food production into an “upstream” process (growing the biomass) and a “downstream” process (purifying, isolating, etc). Molecular farming reduces upstream processing costs, for all the CAPEX- and OPEX-related advantages I discussed above, but makes downstream processing more challenging. In fermentation, you’re usually separating a protein from a liquid broth, which is relatively easy to do. With molecular farming, on the other hand, you’re separating solid target proteins from solid plant proteins.

I’m more optimistic about molecular farming approaches where the non-native protein adds value to the plant in its whole form, as opposed to approaches where the proteins have to be extracted and purified. I’m excited about products like cheesier soybeans, or fortified tofu with heme iron and B12, or oat milk that performs better in a latte – there are so many possibilities to explore.

Climate resilience

The biggest downside of crops is their exposure to extreme weather events like droughts, floods, disease, or worst-case catastrophes like sun-blocking events. While gas fermentation might be the only solution to a true doomsday scenario9, we can and should make crops more resilient to extreme weather. If we imagine weather conditions as a bell curve, I think a sensible strategy would be to develop crops that can survive within a few standard deviations of the mean, and build fermentation facilities for the tails of the distributions.

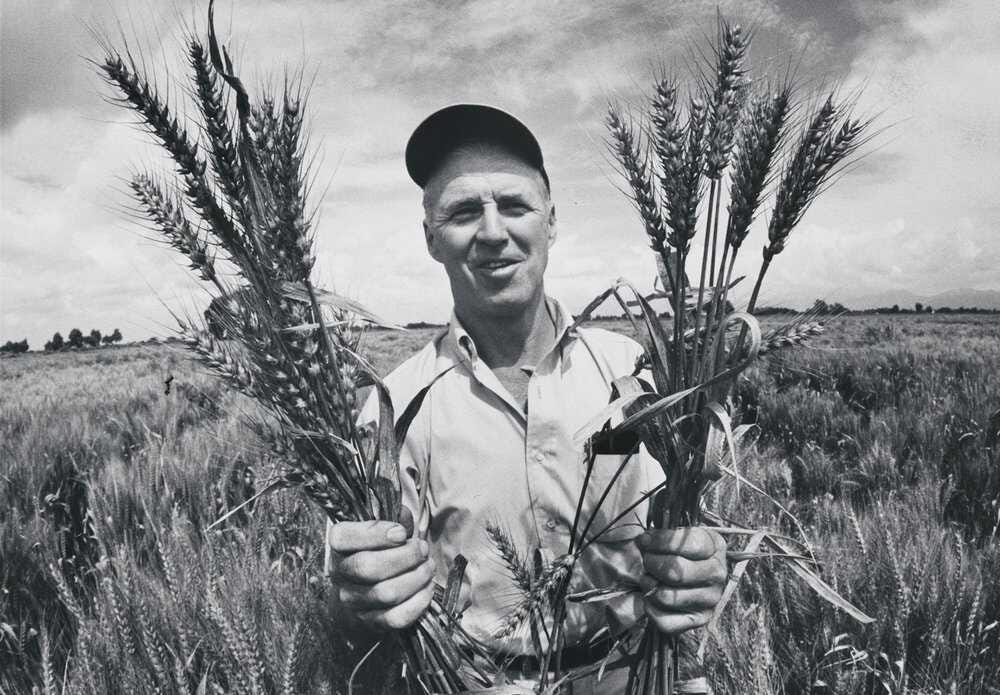

One of history’s semi-unsung heroes is Norman Borlaug, who developed high-yielding varieties of crops in Mexico, India, and Pakistan and turned those regions into net-exporters of food. He made dwarf varieties of wheat that could bear the weight of extra grain, and also combined the genetic disease-resistance of multiple parents into more robust children.

I think climate change will necessitate more of this type of Borlaugian work: creating bespoke crops that solve the problems that the farmers in each region face. Global warming doesn’t make it hotter and drier everywhere; some places will get too little rainfall, some places will get too much, some places will get colder, etc. There won’t be a one-size-fits-all wheat or maize or potato, and we’ll need to develop a library of crops that are suited to each microclimate. Making crop research cheaper and more automated will help us (hopefully) stay one step ahead of climate change and reach underserved markets in places like Sub-Saharan Africa.

Conclusions

Crops will remain the foundation of our food supply

Taking a step back, what can we predict about the future of food? Will it be grown in steel tanks or on cropland? My answer is both, but mostly cropland. And the right answer depends on what and where you’re growing.

In general, it’s hard to beat the cost, simplicity, and scalability of crops for feeding 10B+ people. We looked at proteins, carbohydrates, and fats, and found that commodity crops (e.g soy, wheat, and oil palms) consistently achieve the lowest prices. I think crops will remain the foundation of our food supply, and fermentation or chemical processes will fill in the gaps.

The second green revolution

Others have pointed out that the first “green revolution” was not entirely green. It gave us high-yielding, semi-dwarf varieties of crops that could grow faster, support more grains, and resist disease. But it also involved the widespread introduction of synthetic fertilizers and pesticides and a shift towards intensive monoculture. We’re able to feed billions more people, but not without significant environmental downsides.

In the “second” green revolution, we’ll need to further increase crop yields while undoing the problems caused by the first one. We’ll need to engineer direct or symbiotic nitrogen fixation into more plants to eliminate the ~5% of emissions that come from synthetic fertilizers. We’ll need to improve innate disease and pest resistance to reduce reliance on pesticides. We’ll need to design region-specific crop varieties that can stay a few steps ahead of climate change. And on top of this, we’ll need to boost photosynthetic efficiency so that we can feed more people with less land and water.

In sum, the first green revolution used selective breeding to do more with more; the second will use engineering to do more with less.

Acknowledgments

Thanks to Sebastian Quaade for his helpful feedback.

Appendix

You can find the supplemental information for this essay here.

I think firmware is a more accurate analogy for the genome than software, since it’s embedded in the plant’s cells, not easily modifiable at runtime, and operates over the entire organism’s life cycle. Epigenetics might be closer to software.

Greenhouses still seem to be about an OOM cheaper per square foot or square meter than fermentation facilities. While greenhouse CAPEX is in the O($100/m2) range, fermentation and chemical plants are in the O($1k/m2) range.

Notably, this was demonstrated for the first time using electricity in 2023.

If you play around with the interactive chart and choose some specific countries, you'll notice that the upward trend is not universal. In many regions, crop yields have plateaud.

I wonder what carbon removal companies think about future CO₂ concentrations. If they achieve their mission, we’ll go from more than 420 ppm of CO₂ back down to 280 ppm, a 33% lower concentration. This means that the unit energy costs for DAC will only get higher as progress is made.

And 12% isn’t even a hard limit (see above)! That’s just the limit within the spectrum of radiation that plants can currently use, which could be extended through bioengineering.

While the Haber process is energy intensive, most of the emissions in the fertilizer lifecycle occur during their use on farms. N2O is a potent greenhouse gas!

Synthetic fertilizer, as well as other advances in modern agriculture, have allowed crop yields to outpace population growth.