Future Food #4: Indoor agriculture

Vertical farming is overhyped, but greenhouses will play a key role in climate adaptation and food security

In the last post, I predicted that plants will remain the foundation of our food system, purely for techno-economic reasons ($/kg). Genetic improvements, like drought and disease tolerance or enhanced photosynthetic efficiency will be key for climate adaptation and food security.

Even with advances in synthetic biology and gene editing, reducing the land, water, and fertilizer use of outdoor crops while protecting them against climate change is a formidable challenge. Due to the significant time and capital investment required to bring improved crop varieties to market, existing seed companies almost exclusively focus on large commodity crops (e.g soy, wheat, and corn) in large markets with a proven ROI.

This market failure is a problem, because there is a “long tail” of crops that are of regional or nutritional importance, but largely neglected by crop breeding efforts. How do we protect those crops in the future? I believe localized indoor farming is a large part of the answer.

Why farm indoors?

Advantages

Like synthetic food, indoor farming decouples farming from arable land, enabling agriculture in regions that are too hot, dry, cold, and so on. Indoor farms could turn dry (but sunny!) deserts into agricultural hubs. Indoor farmers don’t have to worry (as much) about storms, floods, droughts, insects, and problems that would be existential outdoors.

Indoor farms save significantly on water, since there are less evaporative losses, irrigation can be more precise, and water respired by plants can be captured and recycled. The importance of agricultural water use is hard to overstate, with some countries using more than 90% of their freshwater for agriculture1.

Indoor farms can generally use less pesticide and herbicide, since the farming environment provides better physical protection2.

The controlled indoor environment can be optimized to maximize yields. By enabling more harvests per year and faster growth, indoor farms can improve upon outdoor yields by an order-of-magnitude in some cases. For example, compare tomato yields in the Netherlands (grown in greenhouses) to yields in basically any other country.

Indoor farms can grow out of season and closer to population centers, improving freshness and reducing transportation emissions (though transport is usually a small share of total emissions). Furthermore, outdoor crops are marked up by aggregators, distributors, and retailers as they criss-cross the globe. Localized indoor farming might be able to cut out one or two these steps, reducing prices for consumers.

Disadvantages

Just like any indoor food pathway, indoor agriculture has one major downside: cost! Growing in an engineered environment introduces significant CAPEX and energy costs. I’ll break down the techno-economics below, but it’s worth knowing that indoor farming CAPEX can be anywhere from ~$50/m2 for a primitive DIY greenhouse to ~$5000/m2 for a high-tech indoor vertical farm. As we’ll see below, high CAPEX rules out the possibility of growing staple crops, like corn, soy, and wheat, indoors.

Terminology

I want to distinguish between two approaches for indoor farming:

Indoor vertical farming (IVF): Growing crops with 100% artificial lighting, usually stacked in multiple vertical layers.

Controlled environment agriculture (CEA): Growing in greenhouses using natural sunlight. Energy might still be used for heating, cooling, and some supplemental lighting.

The key difference is whether artificial lighting is used. As I’ll get into below, the lighting distinction can make or break the techno-economics of indoor farming.

Capital Cost Comparison

To set the stage, it’s helpful to know what it costs to build a greenhouse vs. an indoor vertical farm. I gathered some cost estimates for both types of facilities in this spreadsheet.

Greenhouse CAPEX

Commercial greenhouses seem to cost anywhere from $100-700.

On the high end, this article estimated that Bright Farms built three greenhouses at a cost of $703/m2. I believe this figure is misleadingly high since it’s based on a Series D raise which is probably being used for other purposes.

Agritecture’s indoor farming tool produced a mid-range CAPEX of $195-568/m2, depending on the level of automation.

This blog post covers common greenhouse structures, which cost anywhere from $50-110 for a hoop style to $270-375 for an A-frame.

In summary, $200-500/m2 in total installed CAPEX seems like a representative range for modern commercial greenhouses, including the structure, HVAC, flooring, automation, etc.

Indoor Vertical Farm CAPEX

Vertical farming CAPEX also spans a wide range, from an AeroFarms facility estimated at $6k/m2 to Agritecture estimates of about $2k/m2. These numbers are somewhat misleading, since vertical farms could have multiple floors. On a $/kg basis, the data I’ve gathered suggests that IVFs cost 50-200% more in CAPEX than greenhouses.

In sum, indoor vertical farming CAPEX is in the $2-6k/m2 range. This is an order-of-magnitude higher than greenhouses, but results in ~3-5x higher yield per unit area by going vertical. No matter the comparison metric, IVFs will have higher unit capital costs due to artificial lighting and more significant climate control systems.

Indoor farming is a $/m2 game

Indoor farming is only viable when you earn more revenue per unit area than cost.

CAPEX always provides a lower bound for feasibility. For example, if your greenhouse costs $500/m2 and lasts 10 years, then you need to generate more than $50/m2 of revenue each year to pay back the investment. If your indoor vertical farm costs $5k/m2, then you’d better be producing something really valuable! (You might consider saffron, which is nearly worth its weight in gold.)

How an indoor farm achieves a high $/m2 of revenue can vary. You could grow highly productive crops, highly valuable crops, or ideally both. For example, strawberries, microgreens, and lettuce are fast-growing crops that can be sold at a premium price in stores.

In the chart below, I’ve plotted the lifetime revenue potential of some crops based on their selling price ($/kg, x-axis) and annual yield (tons/ha/year, y-axis). Lifetime revenue might seem like a weird metric, but it allows us to compare revenue and CAPEX on the same chart.

Based on this chart, and the fact that greenhouses cost somewhere in the $200-500/m2 range, you’d predict that cucumbers, tomatoes, eggplant, lettuce, bell peppers, strawberries, figs, and microgreens can be profitably grown in greenhouses. And you’d be right! The crops we farm indoors are the ones that earn enough revenue per square meter to pay back the capital costs. You’d also predict that we’ll never be able to grow wheat3 or soybeans indoors.

What I’m interested in are the crops on the margin of becoming economically viable. If greenhouses got cheaper (e.g, < $100/m2) and crops got more productive, we might see indoor tropical fruits4, avocados, citrus, or potatoes. I’ve baked some optimistic assumptions into yield and price ranges for each crop, so take these with a grain of salt. Achieving the upper end of each yield range would probably involve gene editing and co-optimization of the growing environment. The price ranges are also very uncertain. (The chart is a map but not the territory.)

Artificial lighting will never feed the world

If there’s one point that I’m certain about, it’s that we’ll never produce a meaningful amount of food using artificial lighting. Turning photons into electrons, then back into photons, and then into biomass will never be efficient or cost-effective.

As a motivating example, let’s imagine we wanted to grow a staple crop like soybeans in an indoor vertical farm. We can calculate the lighting cost per kilogram of soybeans, which would set a hard lower bound on selling price. In the chart below, I’ve intentionally created a pie-in-the-sky scenario by stacking a lot of optimistic assumptions on top of each other.

In the base case, I assume that 16 hours per day of clean electricity are available at $0.04/kWh (e.g by co-locating with a solar farm). This is already unrealistic, since the best solar farms get maybe 6-8 hours at full power output. Furthermore, we assume that the farm achieves 4 growing cycles per year (vs. 1 outdoors) and 2x yield on top of that due to more optimal climate control.

Next, I assume that continued solar cost reductions bring the LCOE down to $20/MWh, which seems on-trend by 2030. Next, I assume you can pulse the LEDs so that they’re only on for 50% of the time (some researchers have shown that you can do this while maintaining yields). Next, I model a 50% improvement in LED efficiency. Finally, we add in some genetic engineering breakthroughs, like doubling photosynthetic efficiency. The net result is about ~$1/kg of lighting costs for soybeans, about double the historical high for soybean meal over the last 20 years.

This exercise illustrates why we will never grow commodity crops at scale under artificial lighting: the energy cost precludes price competitiveness.

For completeness, let’s integrate lighting OPEX into our lifetime cost vs. revenue framework. I plotted an indoor farm’s lifetime lighting OPEX as a function of the electricity price. At US industrial grid electricity prices (e.g $60-120/MWH), lighting adds about $2-3k per square meter of crops in lifetime OPEX. With CAPEX + OPEX, the addressable market for IVF shrinks to crops that earn extremely high revenues of >$10k/m2.

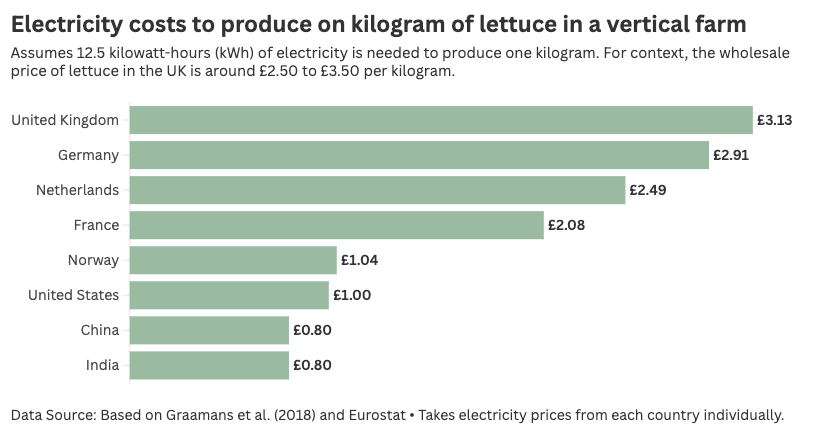

Hannah Ritchie has written an excellent piece about the energy usage of indoor farming, and I’ve included one of the figures below. Using grid electricity, the lighting cost of lettuce is a few dollars (assuming 12.5 kWh per kg of lettuce). The cost of grid electricity is unlikely to decline in the coming decades as more things are electrified.

From a techno-economic perspective, it’s no surprise that the vertical indoor farming industry has crashed and burned over the past few years. You can’t disrupt the food system by selling lettuce that costs $1-3/kg in electricity. Big names like AppHarvest, AeroFarms, Kalera, Fifth Season, and Upward Farms have all declared bankruptcy. These companies are prime examples of ZIRPs and loonshots; they sound good in a pitch deck, but tried to scale unsustainable unit economics.

Greenhouses are a techno-economic sweet spot

Greenhouses make a lot of sense. They leverage free sunlight while using a minimal structure to provide ideal growing conditions. In ideal locations, the “climate control system” can be as low-tech as opening a window or putting shades on the roof. Where vertical farms try to eliminate all natural variation in the environment, greenhouses work with it.

At ~$200-500/m2 of CAPEX (and with no lighting costs), it’s economical to grow a wide variety of foods in greenhouses, like tomatoes, berries, lettuces, vine crops, peppers, tree fruits, and herbs. These crops may seem inconsequential to the global calorie supply, but they play an important role in a healthy and enjoyable diet. And as I mentioned above, innovations that (a) make greenhouses cheaper or (b) make plants more productive will expand the menu of crops we can farm indoors.

We should build more greenhouses to improve access to healthy food and shelter more of food from climate change. Places like Westland in the Netherlands (nicknamed the “glass city”) or Almeria, Spain are an existence proof that this is possible. The question then becomes, where should the next glass city be built?

Building more glass cities

While indoor farming is technically possible anywhere with abundant energy, some places are much more practical than others. Different regions present tradeoffs. For example, arid regions might have abundant lighting and no need for heating, but require significant cooling load during the day. Tropical regions might be at an ideal temperature, but require costly dehumidification.

How do you balance these tradeoffs?

Minimize (or eliminate) supplemental lighting. Lighting is costly to build and operate, and eliminating it completely significantly reduces cost.

Minimize heating, cooling, and humidity control. Greenhouses require specific temperature and humidity ranges during the day and at night. Maintaining these can be costly if you’re fighting against the outdoor environment.

Minimize distance from skilled workers and consumers.

Finding the best sunlight

Sunlight is a non-negotiable requirement5. Using the ERA5 dataset, I mapped the total solar radiation (J/m2/year) for the year 2023. There’s a lot of variation due to latitude, cloud cover, and elevation; regions like Northern Chile, the Sahara desert, Saudi Arabia, Western China, or Australia have 2-3x the solar irradiance of Northern Europe or Alaska.

Based on ideal daily light integrals for horticulture (20-40 mol/m2/day), we’re looking for “goldilocks” regions in the 3.5-7 GJ/m2/year irradiance range. Dark blue or dark red are both suboptimal for most crops.

Surprisingly, the DLI range excludes many sunny places. For example, the level of radiation in the Atacama, Sahara, or Kalahari desert is too intense, and would require shading or more opaque glass to avoid light damage. Simply reflecting away excess light isn’t rocket science, but does add a bit of cost and complexity. The bigger issue is that regions with excess light also tend to have excessive cooling costs (more on this below).

Places with less irradiance, such as Canada, Russia, or Greenland could still farm some lower-light crops indoors. However, latitudes above ~50°N are definitely not where the most productive greenhouses will be sited.

Ideal greenhouse regions are light yellow, and there are a lot of them! There is good lighting in half of the US, most of South America, Spain, Turkey, Central Africa, India, Southeast Asia, and the coasts of Australia, to name a few.

Minimizing heating, cooling, and humidity control

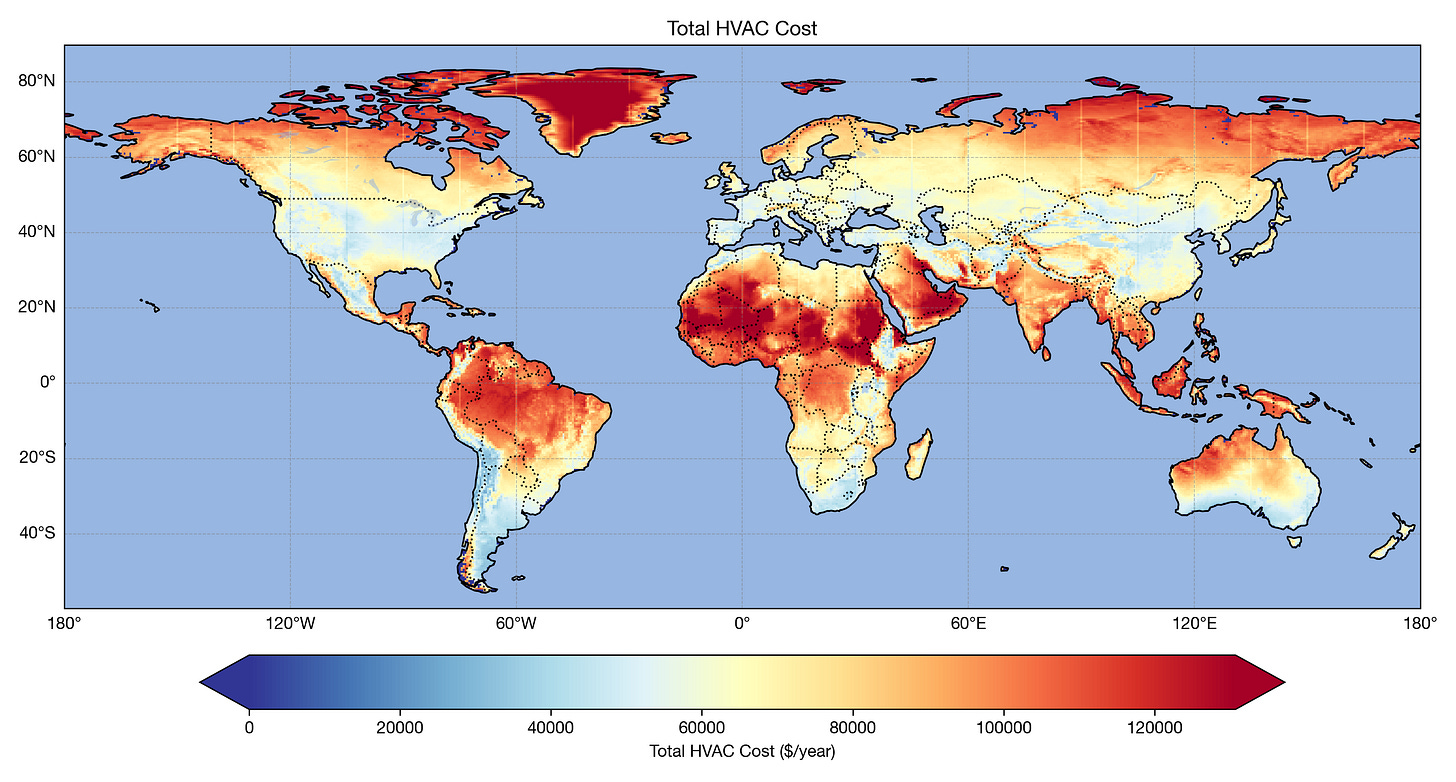

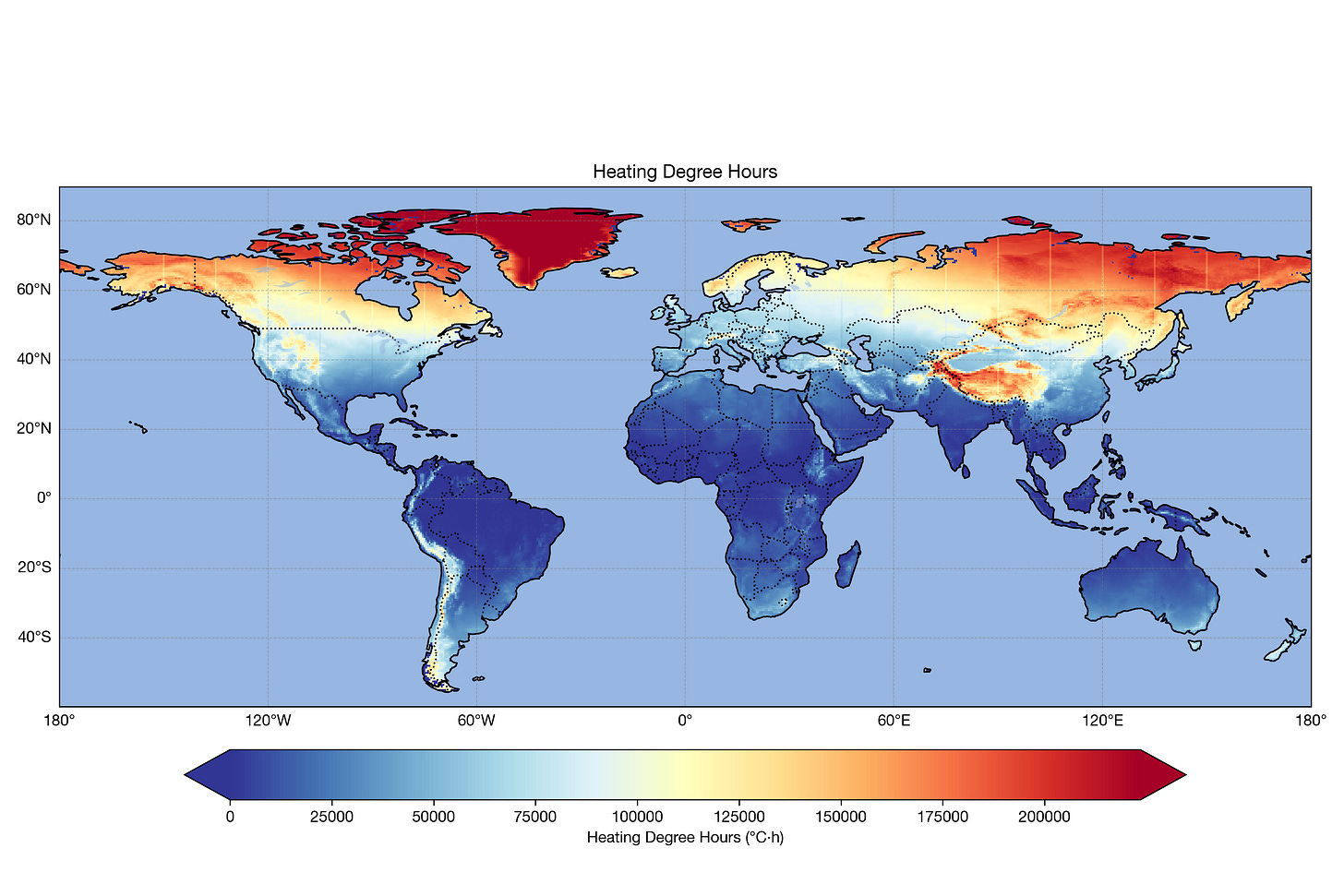

Most places have a tradeoff between heating, cooling, and humidity needs. How do you prioritize those factors? To get an intuition, I modeled a large (10,000 m2 = 1 hectare) commercial greenhouse that must be kept at 24C and 80% humidity during the day and 18C and 70% humidity at night.

1 heating degree-hour (HDH) costs $0.41

1 cooling degree-hour (CDH) costs $1.236

Humidity matters and is expensive to manage. I assume ideal range of no more than 80% during the day, and no more than 70% at night. 1 humidity percent-hour (HPH) costs $0.38.

Greenhouses get a lot of passive solar heating. This provides “free heating” during cold months, but also increases cooling needs during hot months. I capture this (very approximately) by reducing HDHs by 30% and increasing CDHs by 30%7.

Using ERA5 data of hourly temperature and humidity from the year 2023, I wanted to see what HDHs, CDHs, and HPHs look like across the world. Then we can multiply by the cost factors above and add them together to get total HVAC OPEX costs for a model greenhouse across regions8. I’ve plotted the final results below, with intermediate maps in the Appendix.

No place is perfect! In the most ideal environments (light blue), my model greenhouse would still have $5-6/m2/year in HVAC costs. These numbers are conservatively high, and a grower could reduce them by relaxing the temperature/humidity tolerance or using passive methods.

In the worst regions (dark red), costs are upwards of $13/m2/year. This number may seem small, but translates to ~$200/m2 in lifetime OPEX on top of a greenhouse that costs ~$200-500/m2 in CAPEX.

What regions can we rule out?

Places that are both hot and humid: a large portion of Brazil, Southeast Asia, Central Africa

Arid regions that require significant cooling: Saharan Africa, Arabian Peninsula, Northwest Australia

Places that are too cold: northern Canada, northern Russia, Greenland, Alaska

Ideal regions for greenhouses

By overlaying the irradiation and HVAC heat maps, we can compile a shortlist of greenhouse locations with great sunlight and climate. The good news is that there are several promising regions on each continent:

North America: Central Mexico, California, Nevada, the “Great Plains” states (e.g NM, CO, WY), and parts of the Southeast (e.g GA, SC, NC).

South America: Chile, Argentina (with protection from peak solar radiation)

Africa: South Africa, parts of Zimbabwe, Kenya, and Ethiopia

Asia: Turkey, Iran, Afghanistan, northern China, Mongolia

Oceania: the southern coast of Australia

Europe: Spain, Greece, Southern Italy

An indoor farming industry could emerge in any of these regions, and is already prevalent in Central Mexico, Turkey, and northern China, for example.

What’s interesting is that the Netherlands, while known for its indoor farming industry, would not be high on our list due to suboptimal annual light levels. This suggests that non-environmental factors, like proximity to skilled labor and high-value markets are equally important in the siting calculus.

This short data science exercise made me more optimistic about food security and climate resilience. Many regions of the world have solid conditions for low-cost indoor farming. If sites are chosen well, structures can be minimized, and passive climate control systems (ventilation, climate batteries, thermal curtains) can be effective.

Sidenote: Synergies with gene editing

There are two parallel work streams targeted at climate resilient agriculture:

Using gene editing to adapt outdoor crops to changing conditions

Building indoor farms to create optimal environments for crops

The industry often treats these as separate approaches, when in fact they're complementary. Indoor farming creates unique opportunities for crop-environment co-optimization. For example, we could develop:

Dwarf fruit trees designed specifically for greenhouse geometries

Tomato varieties with optimal growth at lower temperatures to reduce heating costs

Crops with enhanced resistance to humidity-loving pathogens

This systems-based approach could yield significant economic and productivity advantages. As the indoor farming industry matures, leaders will increasingly pursue these joint optimization strategies.

Conclusions

Due to lighting costs alone, indoor vertical farming will not become a meaningful part of the food system – just a tool for growing premium lettuce, microgreens, and berries. Extremely wealthy, energy-rich, and land-constrained places like Singapore or the UAE might be the exception.

Greenhouses are a techno-economic sweet spot that get the benefits of indoor agriculture with modest CAPEX and climate control costs.

Gene editing and advances in low-cost greenhouse design will allow a greater variety of crops to be grown cost-competitively indoors. The future will have more fresh fruits and vegetables, not less!

While the majority of calories will continue to be grown outdoors as staple crops, I expect greenhouses to be an indispensable tool in climate adaptation.

Appendix

In some regions, evaporative cooling can be a much larger use of water than irrigation.

Indoor farms might keep out some pests, but close proximity of plants and high humidity increases the risk of pathogens.

Interestingly, a Berlin-based startup called Infarm is trying to grow wheat indoors. They claim to have demonstrated yields of 117 tons/ha (through vertical farming), which is more than 20x typical outdoor yields. I hope they prove me wrong!

If we do start growing more tropical fruits in greenhouses, I propose the de-extinction of Gros Michel bananas to be the first priority! They taste like banana candy (isoamyl acetate), don’t bruise as easily, but unfortunately are very susceptible to fungal pathogens. By providing better containment against weeds, insects, and diseases, indoor farms can help us grow crops that might not be resilient in the wild.

Technically, it isn’t! There is a such thing as electro-agriculture, which I may cover in a future post. It falls into the indoor agriculture category, but is at a low TRL.

There are a lot of factors at play in heating/cooling costs. Cooling has a higher coefficient of performance (COP) (efficiency), but natural gas is cheaper than electricity in most places. The amount of air that has to be heated/cooled depends critically on the infiltration rate of the greenhouse (air changes per hour). I’m assuming higher infiltration during hot hours through increased ventilation.

To properly model a greenhouse, you’d need to set up a differential equation that includes all the sources of incoming and outgoing heat flux (solar radiation, convection, ventilation, ground heat exchange).

Assumes an ideal greenhouse temperature of 24°C during the day (14 hours) and 18°C at night (10 hours). These are somewhat arbitrary, but a reasonable starting point for point for most crops.

This is a great overview of the topic, I'm very impressed with all the modelling.

I have come to similar conclusions. Over time more and more food will be produced in controlled, indoor environments.

Great job very well highlighted the present scenario.